Waste Water Treatment

F.O.G Pre Treatment Plant (Biological Sysm)

(Environment, Social & Govern (ESG) & Net Zero Decarbonization)

PTP or Grey Water PTP is an advance designed technology for control facilities, management and Pretreatment of the oil, Grease, Sludge, food waste and waste water from and after the discharge from the standard type of the Grease Interceptor or Grease Trap. The system provide for the larger size, longer holding and settlement time from a few numbers of pre-fabricated Stainless Steel Reactor Tanks, come with the aeration water treatment chemical products and treatment of F & B, wet market and retail shops/ waste water (Excluding, Toilet waste) for example seafood and animal blood contamination, rotten fat and oil, sludge, food waste, detergent, soap chemical. etc.

The system treatment require is to comply to the public STP (IWK) Intake/

influent parameter of standard B2 Guide line value :

Biological Treatment Plant Operation (Grey Water FOG PTP)

(Environment, Social & Govern (ESG) & Net Zero Decarbonization)

A typical aerobic effluent treatment plant involves three phases of treatment – primary, secondary and tertiary. Primary treatment involves the removal of solids including scum and sludge cakes. Secondary treatment is the major section of the process whereby aeration of the waste water in the presence of the activated sludge bacteria results in the breakdown of impurities. Tertiary treatment may be required to further improve the quality of the effluent prior to discharge and may involve removal of nitrogen, phosphates, suspended solids or pathogens as required.

As the influent enters the aeration tank it mixes with the activated sludge and also a flow of return or recycled activated sludge (RAS). Immediately upon contact with the incoming organic impurities, the resident microbial population in the mixed liquor (MLSS) grows with a concomitant rise in the respiration rate. The soft BOD (easily degradable organic impurities start to decline, followed at a later stage and at a lower rate the more recalcitrant (or hard) BOD). Ideally by the time the mixed liquor reaches the end of the aerobic treatment stage 90- 95% of the effluent BOD should have been removed.

If it reaches this state before the point of discharge there is under utilization of capacity. If however it has not reached this stage at outlet, then the effluent will be discharged into the environment with significant BOD still untreated. Under steady state conditions, the activated sludge that is waste corresponds to the net production of sludge resulting from the growth of biomass during passage through the aeration tank.

- Rapid throughout of waste water

- High rate of BOD removal

- Good sludge settlement post-treatment

- Low rate of sludge production

- Minimal aeration costs

- High quality effluent – low BOD, suspended solid etc.

Grease Interceptor & Sizing (F&B Kitchen)

(Environment, Social & Govern (ESG) & Net Zero Decarbonization)

The kitchen waste water treatment systems invariably requires a large centralized grease interceptor prior to the pretreatment plant. The grease interceptor selected must be able to perform well and be able to remove the grease and oil to the maximum volume. Grease and oil trapped in the interceptor will then be skimmed away into a collection truck during servicing. Selecting the right size of the grease interceptor is based on calculations made on the actual fixture values of the kitchen only. (The Grease Interceptors removal efficiency performance can only remove base on percentage measurement of 99 %).

Biological Treatment Plant Operation ( Grey Water FOG PTP)

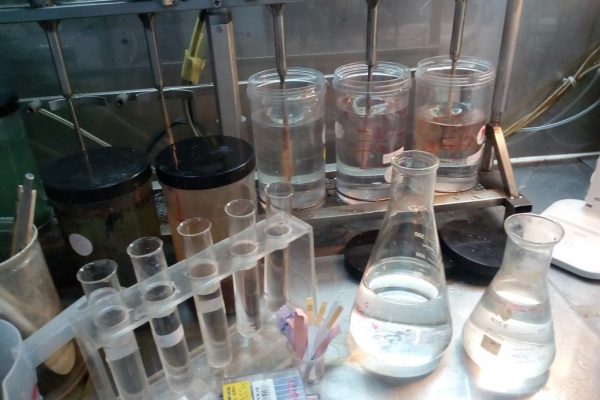

GREYWATEC Pretreatment System is a specially designed biological treatment for F&B Kitchen, Hypermarket (wet market area) waste water. The Plant consist of several prefabricated Stainless Steel Grade 304 Bio reactors tank and sludge concrete sump pits and is complete with pump, aerator and other treatment equipment and Froscozyme products

e.g. (AM S 140 X). (Concrete Chamber by others)

The primary tank CTSR and (RT1) is to further trap and collect solid/sludge cakes or sumps etc. escaping from the grease interceptor effluent.

From RT2 & RT3 reactors are aerated 24 hours a day and enzyme feeding is also recommended. Froscozyme (Amnite S140X) will be dosed into aerated reactors. This is a highly scented, liquid, biological product which rapidly degrades organic solids. The product rapidly reduces COD/BOD levels resulting in reduced operational problems and elimination of malodours.

In this aeration tanks, the bacteria are generally concentrated in floes formed from accumulations of non-living organic polymers. They have a porous structure but are sufficiently resistance to sheer forces exerted during rapid mixing and aeration within the treatment zone. Fine particulates, colloidal particles and large molecules become absorbed to the floes thereby allowing the enzymes secreted by the bacteria within the floes to facilitate their microbial degradation.

Part of the settlement sludge at the bottom of the tank will be dislodged into a sump and the waste water will be pumped back for further treatment once weekly.

The last Reactor (RT Tank 4 & 5 or 6 & 7 ) is the final stage of the process and treatment may be required to further improve the quality of the effluent prior to discharge and may involve removal of nitrogen, phosphates, suspended solid or pathogens as required.

Recommendation for optimum operation of the plant Routine Operating Principles

- Regular check service and maintenance the plant

- Maintain of pH in range 6.5 – 5

- Maintain of DOT at no less than 2 ppm

- Maintain of temperature at 20 – 27 Celsius

- Maintain of MLSS at 7500 ppm

- Sludge harvesting regime should be a little and often so as to minimize shocks to the biological system, and never more than 10% of total at any one time.

PUBLIC STP (IWK) DESIGN INFLUENT VALUES.

- 5-day Biochemical Oxygen Demand(BOD5)=250 mg/l

- Total suspended solid (TSS) = 300 mg/l

- Chemical Oxygen Demand (COD) = 500 mg/l

- Oil and Grease (O&G) = 50 mg/l

- pH = 6~8

- Ammoniacal nitrogen = 30 mg/I

CONDITION OF INSTALLATION AND USE

- Environmental Conditions For Operations:-

- water temperature 95° Fahrenheit ( 35° Celsius)

- water temperature 50° Fahrenheit ( +10° Celsius ) (Optional 77° F)

- PH range of water treated between PH 6.5-8 (optional 7)

- No industrial oil ( Black Oil)

- No Hydrofluoric acid used in car wash area or cleaning procedures

- No black waste water (WC / Toilet)

- No Bleach and / or Quaternary disinfectants allowed in the waste water

- To be preinstalled with Grease, Oil Interceptor and solid sediment Interceptor

- (Removal efficiency for O&G 99% and above)

STRUCTURAL AND ELECTRICAL CONDITIONS:-

- Ventilation System

- Free of Flood water ( Rain)

- The floor has to have a sufficient hardness in order to support the pressure

- Extended by the weight of the equipment tank. To allow space for the Servicing / maintenance of the equipment when

- The Installation area has to be freely accessible for installing / fixing/ moving etc. of the equipment, tank and